On 30th May 2014, during a thunderstorm of unprecedented velocity the wooden core of the 18 feet tall finial at Humayun’s Tomb snapped and the entire finial collapsed on to the roof – 75 feet below. A thorough evaluation of the situation resulted in submission of a detailed report on the conservation strategy on 16th July 2014. The report was approved on 31st December 2014 by the Director-General, ASI following which repair works could commence in 2015.

Titan Company Ltd., as part of its CSR effort, offered to provide the gold required to authentically finish the finial. Titan’s support extended to their undertaking the gilding within their secure factory premises in Hossur and under the supervision of their team of scientists.

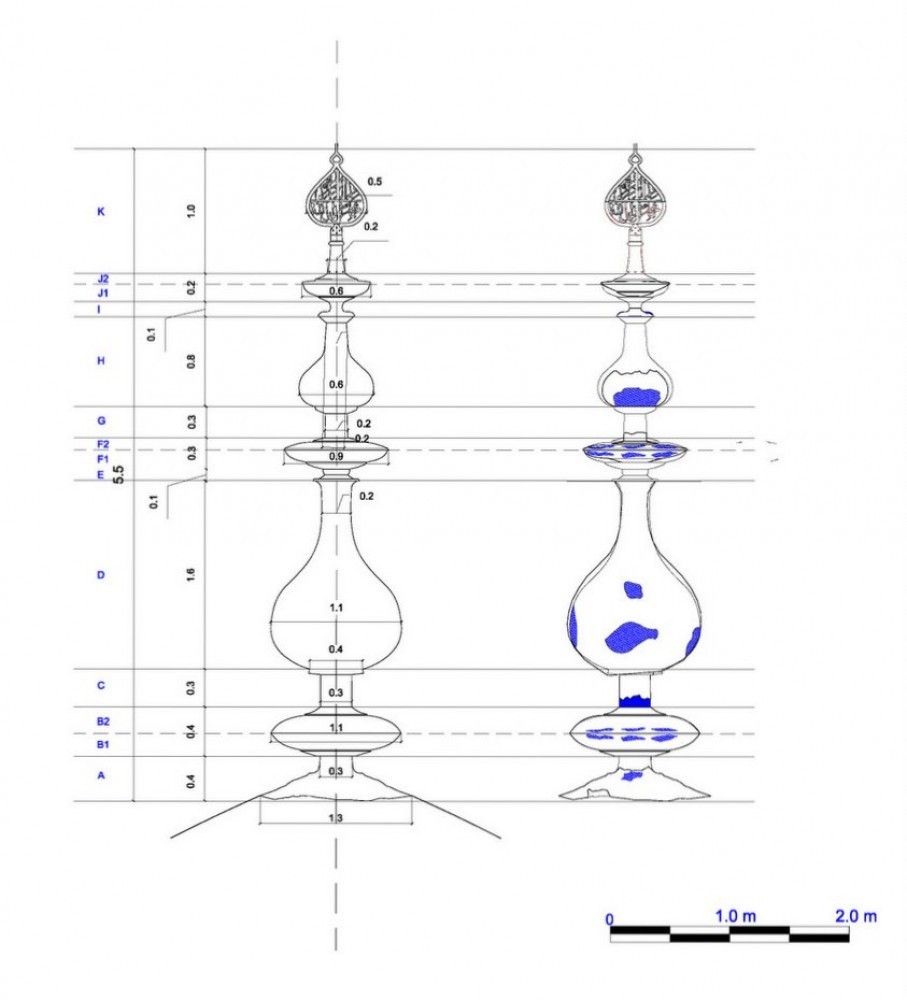

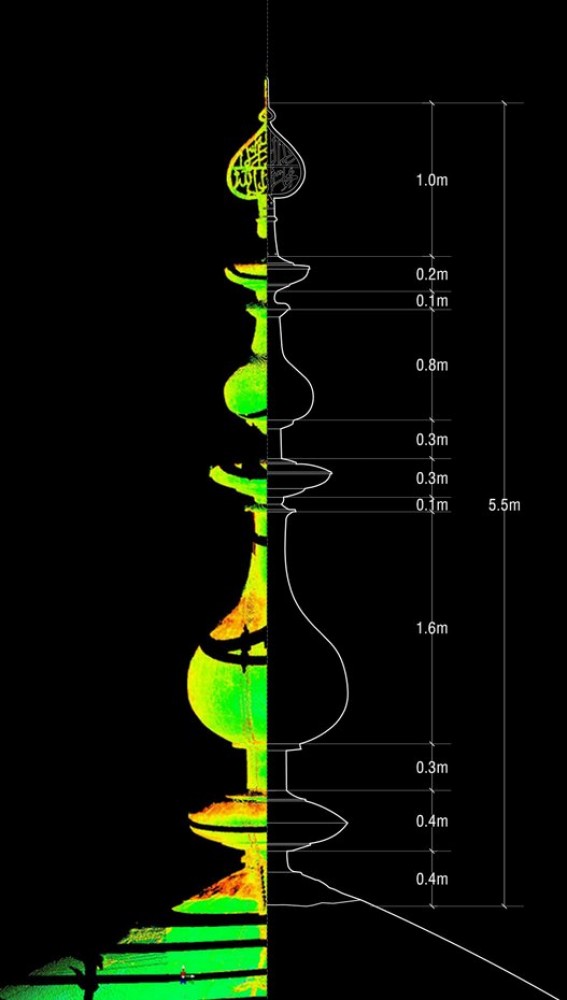

The 18 feet tall finial of Humayun’s Tomb with a core of a 22 foot tree log comprises 11 vessels of pure copper crowned by a brass inscription – the whole finished by the Mughals with layers of pure gold. Humayun’s Tomb, the first of the magnificent mausoleums built by the Mughals, has been symbolic of Mughal creativity and assimilation of architectural elements found in Indian buildings pre-dating the Mughals. The Copper - Gold finial (or Kalash) erected here, seems to have been inspired by Temple architecture and built precisely to fit the dome profile. Later, the Taj Mahal used a similar copper finial.

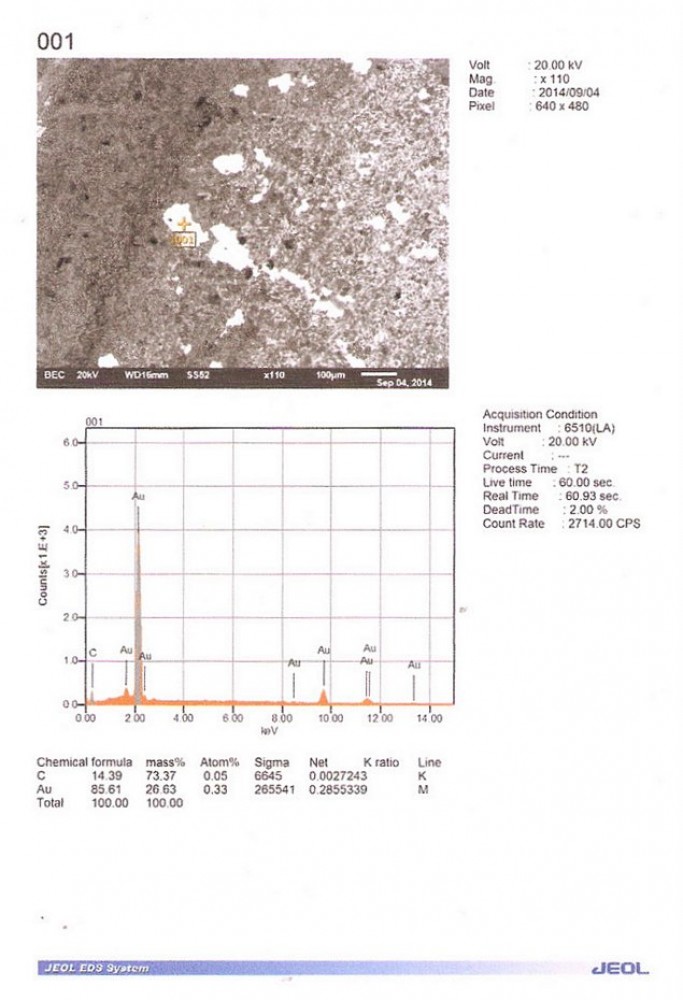

The laboratory analysis of the finial revealed that it was built of almost pure copper and gilded with pure gold leaf. Following the decision to house the original finial in the Humayun's Tomb Interpretation Centre, a replica finial – matching the original in profile, size, weight and shape was prepared. For the restoration of the finial to the dome of Humayun’s Tomb, authenticity was ensured as the new finial should match the original exactly in weight and profile for each of the 11vessels; it is built of material of exactly matching composition (Copper, brass, wood and gold) used by the Mughals in the 16th century; continues to crown the white marble dome - representing the pluralistic architectural traditions employed by the Mughals by their adopting architectural elements from monuments pre-dating their arrival in India; is a product of living craft traditions that have passed-on for generations and centuries in craftsmen families.

Manufacturing of pure copper sheets was especially commissioned as impurities in the copper would result in the deterioration of the final gold layers. Eleven copper vessels were prepared in a traditional workshop in Shahjahanabad by master craftsmen – matching exactly in profile and weight as the original.

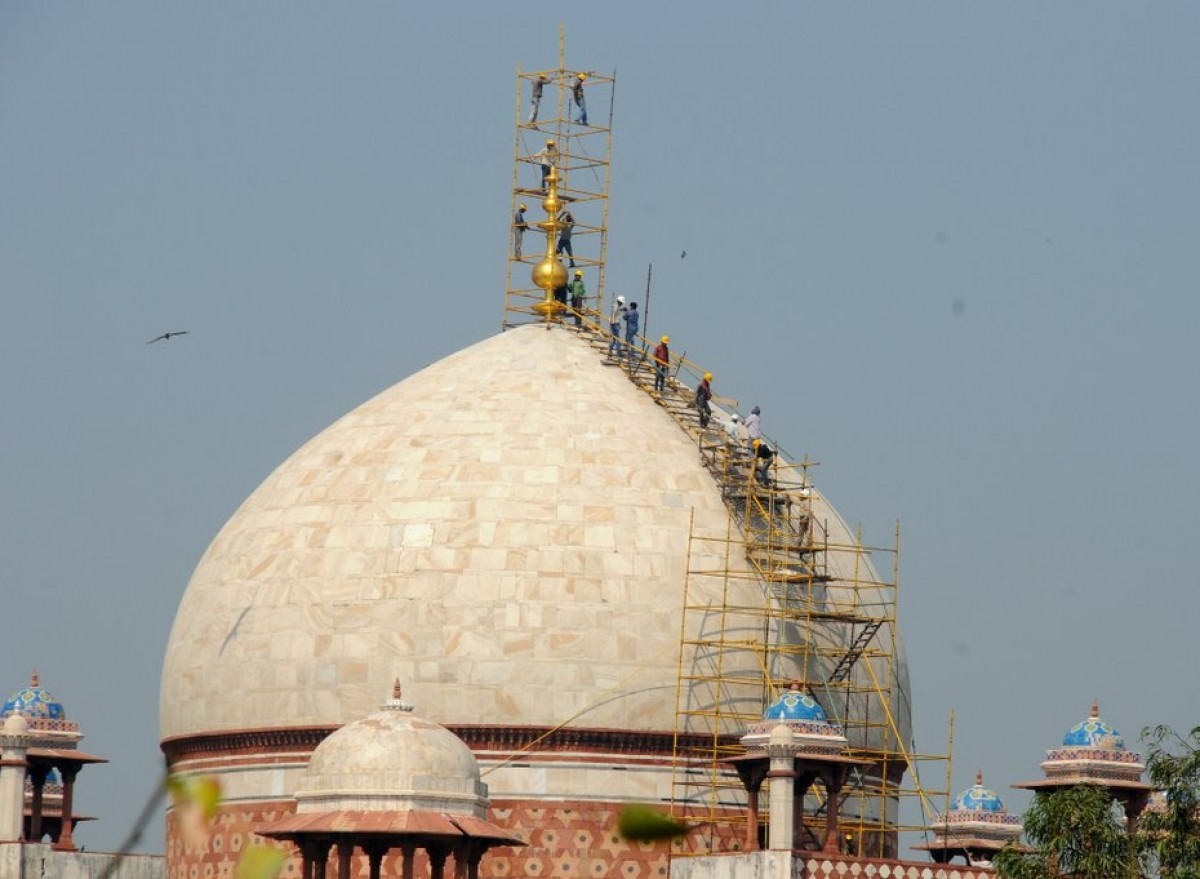

Titan Company Ltd was approached to provide required gold and expertise to ensure an appropriate gilding process. Since the gilding work required a long duration of time the copper finial was installed on the dome in March 2015. This was painted in gold colour. Though not an authentic replacement due to the gold layer missing, this ensured that the integrity of the tomb was not compromised for the long duration required for further analysis, preparing a second replica and gilding.

Based on their expertise in gold work, Titan Company Ltd agreed to gild a full-scale replica of the finial which is expected to require in excess of three kilograms of gold. The gold would be provided by Titan Company Ltd. And a family of traditional gilders would prepare and apply gold leaf on the copper finial pieces in consultation with scientists at Titan Company at their secure factory premises in Hossur, Tamil Nadu.

A second set of copper vessels were prepared with copper sheets especially manufactured of 99.4% purity to ensure impurities in copper do not set off a deterioration process in the final gold layer.

The copper vessels were transported to Titan Company facilities in November 2015 following which the gilding process could commence.

On the completion of the gilding process, the copper-gold vessels were transported back to Delhi and the existing finial was replaced with an authentic replica. The top inscription was made in brass – not as malleable as copper and much more sturdy. This original brass inscription was found to have evidence of several past repairs with several broken fragments riveted to one another and thus included many joints or ‘weak spots’. Though the original inscription was cast in brass, the inscription for the replica finial - though matching in every other respect – was laser cut from a single brass sheet - thus ensuring accuracy in exactly matching the original.

The brass inscription, as with the copper vessels was gilded.

The weakest link in the finial was its wooden core on account of it being susceptible to deterioration caused by rainwater. Since a significant portion of the wooden shaft was embedded in the dome masonry a tree log of 22 feet height was procured and carved to the original octagonal profile. In order to prevent a repeated snapping, the base of the tree-log was encased in a thin sheet of copper up till the top of the dome. Once erected absolutely vertically, the copper vessels were dropped down on the shaft from its top end, almost 160 feet (equal to a 16 floor building) above ground level. The installation of the Gold Finial on the dome was itself a herculean, risky and challenging process. Led by Aga Khan Trust for Culture engineers, a team of experienced craftsmen first erected the 22 feet tree-log, weighing 1450 kilos to be erected precisely vertical within the dome masonry and fitted with lime mortar.

Each copper-gold vessel was then set on the wooden core with care taken not to scratch the gilding. The entire process was simultaneously monitored from several points within the complex including from atop the scaffolding.

The new gold finial was unveiled by Dr. Mahesh Sharma, Hon’ble Minister of Culture (Govt. of India), in the presence of Dr Rakesh Tiwari, Director-General (ASI), and Mr. Bhaskar Bhat, Managing Director (Titan Company Ltd.) on 19-April 2016.

The understanding of the significance of the 16th century finial as well as the damage the copper-gold vessels suffered in the 2014 collapse led to the agreement that following repairs to the vessels the finial should be preserved and displayed in the secure environment of the proposed Humayun’s Tomb Interpretation Centre. The finial will thus be a centre-piece of the Interpretation Centre. Access to the finial in a museum environment for scholars and scientists will, it is hoped, lead to further research that sheds light on both the pluralistic architectural traditions of the Mughals as well as scientific achievement in 16th century India.

- The Gold Finial Restored

- The Restoration Process : A visual journey

- Interview of Mr Bhaskar Bhat, Managing Director, Titan Company Ltd.

- Unveiling of Gold Finial: Speech by Dr. Mahesh Sharma, Minister of Culture, Government of India

- Unveiling of Gold Finial: Speech by Dr. Rakesh Tiwari, Director-General, Archaeological Survey of India

- Hit by storm, repair on Humayun’s Tomb dome begins

- Humayun's tomb gets crowned in 24-carat gold

- Humayun's tomb gets new finial

- Humayun's Tomb new finial is dressed in gold

- Humayun's Tomb Gets Golden Touch

- New Finial Unveiled at Humayun's Tomb

- Gold finial at Humayun's Tomb unveiled

- Emperor gets his crown back

- Humayun Tomb gets its iconic crown back

- 22-Carat Splendour

- 2 Years on, gilded finial back in Humayun Tomb's crown

- The Golden touch